Hill Engineering is now known as one of the UK & Ireland’s market leaders in quick couplers. 2014 sees Hill bring another ground breaking product to market – the new TEFRA Tilt Coupler which will be on display at Hillhead 2014 at Buxton Quarry. Hill will also be exhibiting the TEFRA hydraulic quick-coupler and a selection of the company’s Titan bucket range.

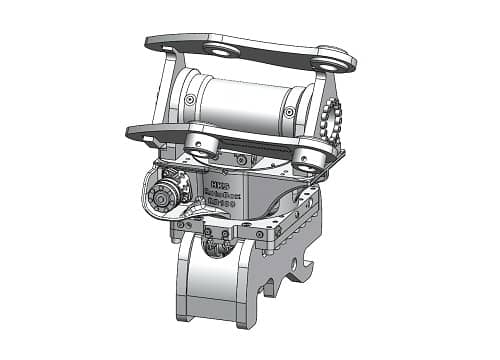

The new TEFRA Tilt Coupler product takes all the advantages of the award winning TEFRA Coupler, and Hill says it provides its customers with the added benefit of increased productivity and versatility in multiple applications. The attachment will be available for machines sizes ranging from 7-55 tonne, and like the TEFRA Coupler, it’s been specifically designed to be almost maintenance free and is fully compliant with the proposed new global safety standard ISO 13031expected later this year.

The heavy duty motor is self-lubricating and there is no requirement to grease the tilt mechanism. Additional to this, Hill has reduced potential wear items so it says users have peace of mind regarding any wear on pins or bushes.

The new TEFRA Tilt Coupler boasts advance technology from German manufacturers HKS, Hill Engineering purchase all its parts from HKS (with the exception of the Coupler of course!). Power Actuator XtraTilt is the magic behind Hill’s new attachment. The robust design of the individual components of the Xtra Tilt, made from high strength, surface hardened materials, allows rotation almost without play, even after prolonged operation.

The swivel mechanism of the Power Actuators is based on the coarse thread principle. The linear movement of the piston, when pressure is applied, is converted by multiple opposing coarse threads on the housing, piston and shaft to a powerful rotary movement. If the hydraulic circuit is closed by the adjusting valve, which at the same time prevents movement of the piston and shaft, the attached coupler remains in any required working position!

Hill Engineering will also be launching the new TiltRotate at Hillhead…

The new Hill TiltRotate, makes its World Debut at Hillhead. The system supports hydraulic excavators with two new functions: The shovel is able to rotate continually and can tilt up to 110°, 55° in both directions – this enables the operator to open up new areas of operation. The operator does not have to shut the excavator as often because the flexibility of the TiltRotate and the radius of action are increased significantly. These operations are likely to increase productivity and save time and money, say Hill! Maximum benefit can be derived from this new attachment, particularly in track laying, because the freedom of movement of 2-way excavators is very limited.

Hill also report that a major technical advantage which the TiltRotate offers, compared to other manufacturers, is its cylinder-less construction, the compact XtraTilt Power Actuator replaces the wider cylinder variant, liable to faults, with a maximum of +45° tilt angle. Because of the slightly higher structure of the TiltRotate the excavator loses relatively little in terms of breakout and ripping power.

For normal use in the garden and landscaping sector, road building etc the breakout power is not as important, however, if very high breakout and ripping forces are required, TiltRotate can be broken down into individual modules or can also be used as a sandwich solution.

Ian Hill – managing director, Hill Engineering said, “Hill Engineering is pleased to have the opportunity to launch this product on our 20th anniversary at the Hillhead show. This gives us the perfect setting to introduce this versatile product to our UK customer base. These trade shows are a key part of our growth strategy, as it provides the perfect opportunity to listen to our customers feedback so we can add even greater value to their businesses moving forward. The TEFRA has led to 30% year on year growth for Hill and with further significant growth projected we expect an additional 30 jobs to be created this year.”

Source: Hill Engineering

Latest Events News

- Build Your House Saudi & Inspire for Home KSA Launch in Riyadh — Bringing Qatar’s Premier Home & Lifestyle Exhibitions to the Kingdom

- AICE 2026 SMM Aluminum Industry Expo to Open in Suzhou, China in April 8-10th, 2026

- Executive Hire Show 2026: a closer look at what visitors can expect

- CLNB 2026: The Global Hub for Battery and New Energy Innovation

- Top International Construction Machinery Brands at SAMOTER 2026

Constructionshows

Constructionshows