An advanced load management system, combined with best-in-class stability and lifting capacity, make the Volvo PL3005D one of the industry’s safest and most productive pipelayers yet.

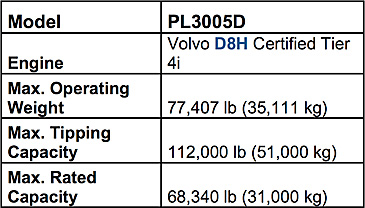

The revolutionary excavator-based PL3005D pipelayer from Volvo offers an unbeatable combination of superior stability with a 50 ton lifting capacity, producing not only one of the most productive machines in the sector – but also one of the safest.

Thanks to its ability to swing the superstructure through 360 degrees, the PL3005D can handle large, heavy pipes with ease, and place them anywhere around the machine – an ability unthinkable with traditional side boom pipelayers. The patented design of the PL3005D marks other significant technical advances over traditional side boom pipelayers, not just its superior stability but, if needed, also its ability to swap booms and convert into a standard excavator configuration. A digging kit is available and the hydraulics are optimized for both pipelayer and excavator operations. With up to 80% common parts with its sibling Volvo excavator, the servicing, wear parts replacement and maintenance requirements of having a PL3005D in the fleet is considerably eased.

Safety and stability

Safety lies at the forefront of Volvo’s pipelayer design. Not only can the PL3005D lay pipes all around the machine, it can also operate on slopes of up to 30 degrees and rugged terrain. A heavy-duty mechanical slew lock firmly fixes the superstructure at any angle in relation to the undercarriage, protecting the transmission and useful when securing the load at a fixed position or during tie-in operations. The undercarriage has a high ground clearance, allowing operation in rugged conditions. A solid footing is secured thanks to 24 in. (600mm) tracks – which can upgraded to wider 32 in. (800mm) tracks for added stability and lower ground pressure. This extra girth doesn’t hamper convenience, as the PL3005D can be transported without the need to disassemble major components, reducing fleet transport times notably.

Volvo pipelayers feature long booms that offer higher hook heights and longer reach, allowing the machine to lift and lower pipes at a safe distance from the trench. If needed a boom extension is also available, offering additional reach and hook height. The PL3005D features a heavy counterweight as standard for additional stability. A mechanical anti two-block with wireless sensor prevents the winch blocks from coming into contact during lifting. Inside the cab, the high pull winch can be operated using the operator’s preferred joystick. A Mode Switch boosts performance, using split pump flow for better load controllability during simultaneous travel/lift operations – or combined flow for maximum performance speed when travelling or in stationary pipe laying operations. A Fine work mode gives high pressure and low flow for maximum lifting power yet minimal fuel use.

Load management system

Safety and ease of operation are facilitated by the PL3005D’s exclusive Load Management System (LMS). The LMS enables the operator to see what weight can be safely lifted at any position relative to the slope. Using inputs from the hook, boom and base machine-mounted sensors enables the system to monitor boom angle, machine orientation and inclination. The computer uses this information to constantly calculate and display actual loads and related working loads, all in real time. The operator receives relevant information, together with graphic displays, on an in-cab monitor. There are also visible and audible warning signals that notify when the safe load limit is reached, including green/yellow/red light bars on both sides of the boom.

Operators work in a clean, low vibration and low noise environment, thanks to Volvo’s latest generation cab. Controls that fall easily to hand and filtered, managed air handling systems help reduce fatigue and stress – and consequently improve productivity. Good all-round visibility is provided thanks to large glazed areas – and also to the elevated riser system fitted to the cab. This hydraulic four bar cab riser gives operators excellent visibility of the load, worksite and into the trench. (The lowest position is ideal when transporting the pipelayer.) Visibility is improved further via standard fit rear and side view cameras, projected via the color monitor inside the cab. The cab is ROPS certified to ISO 3471 & EN474-1 (factory installed only).

The PL3005 has other important features fitted as standard, not least Volvo’s state-of-the-art CareTrack telematics system. CareTrack manages a machine’s productivity and maximizes its availability for work. Using a GPRS mobile network or satellite technology, the system reads information on a wide range of machine data, such as location, fuel consumption and service reminders. That data is then made available securely to any remote online connection. In addition, Volvo provides a three year CareTrack service subscription at no additional cost.

Other notables are the Attachment Management System, that stores up to 18 presets and allows hydraulic flow (standard) and pressure (as an option) to be adjusted, enabling the easy use of a variety of attachments. Maintenance is aided by grouped filters and service points, accessed at ground level via large, wide opening doors.

Specifications

Source: Volvo News Room

Tags News

Constructionshows

Constructionshows