Li Yu Shan Mining keeps its durable Volvo B-Series excavators in good health thanks to routine maintenance, courtesy of Volvo Construction Equipment.

Resting on the coast of Eastern China is the ancient province of Zhejiang. Situated 60km (37mi) from the provincial capital, Hangzhou, and 200km (120mi) from Shanghai, the subtropical region – often thought of as one of the cradles of the Chinese civilization – of Zhejiang maintains a comfortable distance from the bustling cities on its borders, offering tourists a cool and lofty summer retreat from the scorching cities.

Hidden deep within the dense bamboo forests of Moganshan is Li Yu Shan Mining Co Ltd. The quarrying company is renowned in the region for producing small and medium-sized aggregate of 20-25mm and 50-60mm. A third of its output is used as base material for the thousands of kilometers of high-speed railway tracks that crisscross China. A relatively cheap commodity, the product sells for 48-50 RMB (€6.5/$7.4) per tonne.

Beating the odds

Beating the odds

Li Yu Shan Mining has built a solid reputation in China as a quarrying specialist, producing 1.5 million tonnes of material in 2015. The company was enjoying steady growth until the Chinese hit the brakes, causing it – and many construction companies to contract.

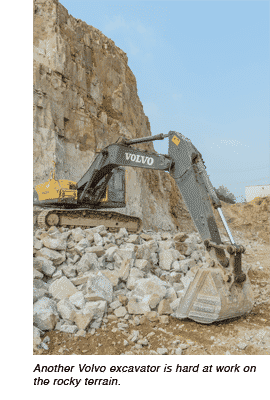

Because of the relative slowdown and consequent lower utilization rates of equipment, contractors are tending to keep machines for longer. The key to customer success when doing this is to take special care of their machines. Thanks to sensible routine maintenance and scheduled servicing Li Yu Shan Mining has prevailed, and is again growing its staff of 60 and machine line-up. Since 2010, the company has purchased seven EC210B and two EC240B models from its local Volvo dealer, Zhejiang Liyang Machinery, based in Deqing, Zhejiang.

Digging deep

The EC210B and EC240B excavators are equipped with a high-strength boom and arm, allowing excavating depths of up to 6m (20ft). To maintain stability on the rocky terrain, the machines also feature robust X-shaped frames, made of high tensile steel, to ensure a long service life.

When purchasing the equipment, quarry operations manager, Yuan Jian Zhong was impressed by the good fuel economy offered by the Volvo B-series excavators. “Volvo excavators typically consume 14-15 liters (3.1-3.2 gal) per hour, that, when compared to competitor models that often average 19 liters, translates into significant financial savings,” he explains.

Greater savings have allowed Li Yu Shan Mining to expand both its operations and fleet. Recently, the company put down a three million RMB (€400,000/$450,000) deposit for the first three of a batch of 15 Volvo EC380D excavators for work on an upcoming mining project.

With over 15 years’ experience of owning and operating quarry equipment, Yuan is satisfied with his decision to choose Volvo. “I switched to Volvo on the advice of friends and colleagues who highlighted their better performance and after-sales service,” he adds.

Rock on

Ensuring the machines remain in optimum working condition is the job of Zhejiang Liyang Machinery. Managing the maintenance of more than 1,000 machines in Zhejiang alone, the Volvo dealership uses Volvo’s remote telematics, CareTrack to alert customers of impending maintenance deadlines.

As Volvo CE continues to advance its technology, so too will construction companies. Smart solutions, plus the durability and high performance provided by Volvo machines, ensure companies like Li Yu Shan Mining reap the riches of the deep with more projects on the horizon.

Tags volvoce

Constructionshows

Constructionshows