For the first time, the state road construction authorities in the German state of Saxony-Anhalt have tested a new temperature measurement system during a partial resurfacing of the A14 near Magdeburg. With the MOBA PAVE-IR™ Scan system, the temperature is measured over the entire area during paving. Using this data, it is possible to draw conclusions about possible weak points in the road.

In the first section the PAVE-IR system scanned the asphalt temperature over a width of about 8.50 metres

More and more vehicles travel motorways and place increasing strain on the roadways. Due to these high loads and because of construction defects, roads often crack after just a few years and potholes and ruts form. This also means additional work for new construction and maintenance measures. The number of traffic jams is increasing as well, leading to immense, secondary economic costs. At the same time, the costs for road construction in Germany have risen by one fourth since just 2005. This makes it all the more important for the responsible authorities to achieve optimum results when constructing and resurfacing roads in order to increase the longevity of the roadways and avoid premature repair work and, thus, additional costs. This applies for the Saxony-Anhalt state road construction authority (LSBB) as well, which is responsible for the construction and maintenance of roadways in Saxony-Anhalt. In cooperation with the construction company Matthäi, the LSBB therefore tested the PAVE-IR™ Scan quality control system for temperature measurement during asphalt paving.

The challenge

Because the LSBB is responsible not only for the tendering of construction projects, but also for inspections during the construction work, they inspect the building materials, the paving process and the completed roads for all projects. The results of the inspections are decisive for approval, billing and the guarantee which the company that performs the work must provide, for example if faulty material is used during paving.

In addition to inspections of the asphalt mix during paving, selective core samples are taken upon completion of the project. These core samples are used to, among other things, determine the compaction and the void content of the paved layers and, thus, test the quality of the road.

Now there is a new possibility to control quality: The PAVE-IR Scan system allows monitoring the temperature over the entire project during asphalt paving. For the first time, the LSBB tested this new quality control system which measures the temperature via scanner and records all data. Using this temperature profile, the paving process can be monitored, documented and conclusions drawn about the uniformity of the asphalt paving.

In the second section, the width of the resurfacing of 10.50 metres was also completely scanned

The project

The LSBB was the first state construction authority in Germany to have used the MOBA PAVE-IR™ Scan temperature measurement system at a construction site, which was located on the A14 near Magdeburg. Approximately 15,000 motor vehicles roll over the ageing motorway every day. In a first section, the northward lane was repaved. The concrete surface was removed on a section approximately one kilometre long over a width of about 8.50 metres. A new asphalt binder layer and asphalt surface layer were then paved. Matthäi, the building contractor, performed the work with hot-on-hot paving, in which two pavers, travelling one behind the other, paved the binder layer and surface layer as compact asphalt. The components of the PAVE-IR™ Scan system were installed on the paver used for the surface layer. The temperature of the binder layer was also recorded. During the second phase of construction, paving was performed over a width of 10.50 metres.

How it works

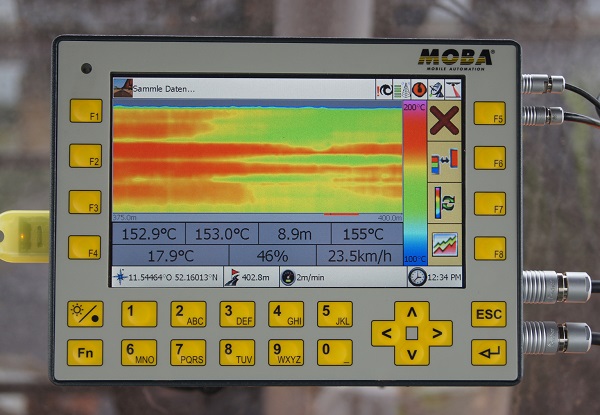

PAVE-IR™ Scan consists of a temperature scanner, a GNSS antenna for precise position determination and an on-board computer. Additional, optional sensors, such as a weather station or individual temperature sensors, can be integrated. At the start of the project, the user enters the project data, for example the starting location and the kilometre point, using the on-board computer. The temperature of the surface layer is measured by the infrared scanner over the entire paving width. For this purpose, the sensor scans the paved asphalt temperature every 25 centimetres with an accuracy of plus/minus two degrees Celsius.

"Previously, it was only possible to measure the temperature on a random basis. With the system, this is possible over the entire area and continuously for the entire project", explains engineer Guido Schwabe, who oversees the construction work on behalf of the LSBB. The current position data as well as the waypoints are recorded by the system via a GNSS antenna. This information can, however, also be complemented by the machine data. All temperature data is displayed on the on-board computer as measurement points together with data such as wind speed, air temperature and humidity, position data, distance covered and average speed of the paver. At the same time, all of this information is stored for documentation and evaluation.

To function reliably at the construction site, all electronic components in the system are specially protected for use outdoors against penetration by dust and water and against damage by heat and vibrations.

Scanner, weather station and GNSS antenna are mounted space savingly and without impeding the personnel on a simple square tube

The results

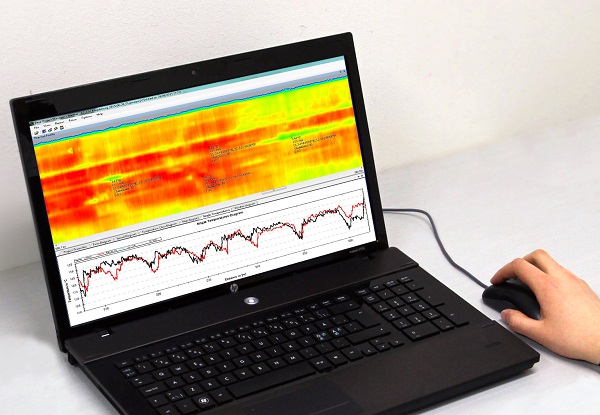

Upon completion of the paving work, the stored data was evaluated with the PAVE Project Manager software. The temperature profile, which was recorded for the entire construction project, clearly shows how hot the asphalt was during paving at a given position. In this way, it is possible to draw conclusions about the quality of the road, since the temperature during paving is a decisive factor for a high-quality result. The data and the knowledge gleaned from it can be used to improve the entire construction process for future construction sites. For example, the temperature profile can be used to better coordinate cooperation between the paver and the asphalt mixing plant in order to optimise the delivery and availability of the material. Because only if all processes are ideally matched to one another can the best-possible result be achieved. Through the visual display of the temperature profile in real time, construction management and the personnel at the paver can directly respond if temperatures fluctuate and can inform the mixing plant or the roller driver.

The PAVE-IR panel displays the temperature profile and all other important information to the personnel

The consequences

The system offers a possibility for monitoring asphalt paving over the entire area and during the entire project. Benefiting from this are not only the authorities, but also the construction company hired to perform the work: using the collected data, weak points in the construction process can be identified and then optimised. This applies not only to the temperature of the mixture, but to other factors as well: for example, with the help of the recorded wind profile, one can clearly see what effects wind has on the asphalt temperature. If paving temperatures are higher on the side that is sheltered from the wind, one can deduce that the wind cools both the material as well as the screed on the wind side – the result: the asphalt temperature drops. This can be countered, for example, by more strongly heating the affected side of the screed to achieve a uniform paving temperature.

The thought behind this is that direct monitoring and process optimisation can be used to obtain a better result, prevent premature damages and thereby save money, such as the costs that would be incurred during repair work. To optimise processes, they must first be measured and analysed. This system makes it possible.

All data can be analyzed with the PAVE Project Manager

During the resurfacing of a state road in the coming year, the LSBB will again use the PAVE-IR™ Scan and, following this second test project, decide how to integrate this new option in tenders. "The initial use was very positive. We can see great advantages in using the system. For the first time, it is possible to monitor the temperature over the entire area and thereby perform an indirect quality control for entire projects. This can be used both as a control tool and as an optimisation instrument. The temperature profile benefits not only us as authorities, but it also serves as proof of good work for the construction company", says Dittmar Marquordt, department head of LSBB Saxony-Anhalt. "We at the LSBB can imagine incorporating such a system as a standard part of tenders for larger projects", adds Marquordt.

After the end of the first test series, there will be further PAVE-IR tests at the beginning of 2014. The system is expected to be available for the European market in early summer 2014.

Photos: MOBA

Source: MOBA Mobile Automation AG

Constructionshows

Constructionshows