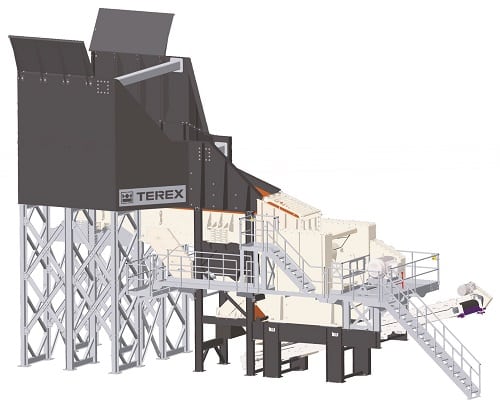

CEDAR RAPIDS, IOWA, August, 2014 – Terex Minerals Processing Systems (MPS) has launched the new MJ47 primary jaw crusher module, increasing the application capabilities and crushing capacity of its existing modular product range with their largest jaw module to date. The Terex® MJ47 jaw crusher module is designed for large quarries or contractors that want a stationary type design without the complexity of a normal stick-built plant.

The MJ47 module features the robust, 36″ x 48″ (914mm x 1219mm) Terex® Jaques ST47 jaw crusher.

Other key features include the Terex® Simplicity 51″ x 24′ (1.3 m x 7.3 m) heavy-duty double-deck vibrating grizzly feeder, large capacity truck dump hopper, discharge conveyor, extra heavy-duty galvanized/ painted I-beam frame, wrap-around maintenance access platform, stairs and guard rails.

The modular product line consists of several pre-designed static and semi-static crushing and screening “plug and play” modules. Set-up time and ease of operation is aided by the simplicity of the modular product range. Modules are designed to fit and work together interchangeably. All Terex MPS modules bolt together on site and require minimal on-site wiring.

For more information on Terex Minerals Processing Systems crushing and screening products or customer support please contact your local distributor. Details can be found at www.terexmps.com.

Terex Minerals Processing Systems

909 17th Street NE

Cedar Rapids, Iowa 52402 USA

Tags Terex

Constructionshows

Constructionshows