Engineers at Volvo Construction Equipment are developing Intelligent Transport Systems (ITS) which could reduce fuel consumption by up to 30% in certain applications and increase safety.

Fuel efficiency is a top priority for construction equipment owners. That’s why hundreds of engineers in Volvo Construction Equipment’s (Volvo CE’s) Technology function are busy working on clever innovations to make equipment as fuel efficient as possible. One area of technological development is machine-to-machine (M2M) and machine-to-infrastructure (M2I) communication.

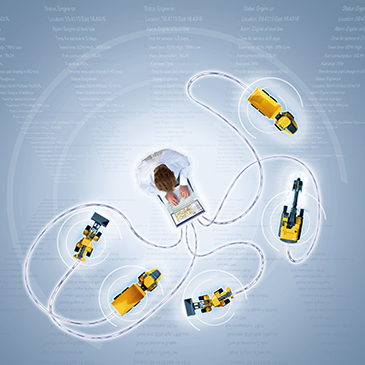

“One of the advanced engineering projects we’re working on is wireless machine communication technology,” says Peter Wallin, research coordinator at Volvo CE. “By increasing machine intelligence and making it possible for machines to ‘talk’ to each other we can reduce operational costs through improved fuel efficiency, while also increasing safety and maintaining productivity. So far we’ve looked at the quarry and aggregates segment and road construction – but this technology can be used in all the applications Volvo machines work in.”

Fleet optimization

Volvo CE has conducted tests to calculate the potential fuel savings M2M communication could bring to articulated haulers working in the quarry and aggregates segment. The project monitored a hauler, loaded with rocks from an excavator, travelling to the crushing site. The machine was fitted with an internal measurement system to verify the fuel consumption. The hauler was operated by different drivers, at both constant and varied speeds, with different amounts of idle time and both with and without stops along the way. Tests showed that when the hauler travelled faster than necessary to the crusher, and as a result had to wait before unloading, fuel consumption was up to 30% higher compared to when the hauler travelled at a constant speed and arrived at the optimum moment.

“In conjunction with the tests carried out in Braås, Sweden, we’ve visited customer sites and monitored how the machines are used,” says Peter. “Today sites aren’t optimized and usually there isn’t a structure stating when the haulers should arrive at the crusher. Often the machines are driven at maximum speed but when you look at the amount of idle time it’s clear that this isn’t always necessary. When the machines are stationary, waiting to unload, they’re wasting time and money. By using M2M communication the operator would know exactly when to arrive at the crusher and what speed to travel at to get there. Through reducing machine speed and idle time we are reducing fuel consumption and wear and tear on the machine as well as facilitating an efficient flow of equipment.”

Looking to the future

“The next stage of the project will be to provide the operator with information – such as target speed and arrival time – inside the cab,” says Peter. “This live information will support and guide operators to the most fuel efficient operation and could be presented in future concepts like heads-up displays and other innovative approaches. If all the equipment on a job site was fitted with this technology the machines could be linked to a central control point – such as a tablet device used by the site manager to optimize the efficiency of the fleet. The results from this project will determine if, when and how this technology will reach the market.”

Active safety

“An undoubted advantage of increased machine intelligence is the ability to introduce active safety,” concludes Peter. “Volvo has set itself the target of reducing accidents relating to its equipment to zero – and future technology like M2M communication will play a major part in achieving this ambition. For example, if we combined M2M communication technology with an automatic braking system it would prevent the possibility of a collision between two Volvo machines – and by equipping site workers with a wireless beamer or a transmitter, machines could also detect and avoid humans in the vicinity.”

Source: Volvo News Room

Tags News

Constructionshows

Constructionshows